02OCT2022

Tom and I spent a few hours cutting the fuel sender hole into one tank. We used an adjustable hole cutter that we got from Harbor Freight because we couldn't find the right size hole saw at local stores. This cutter wasn't really made for metal and it took a long time to cut through the tank, lol. It got the job done, but I'm going to order a hole saw in the right size for the other one. (I didn't get this work on video)

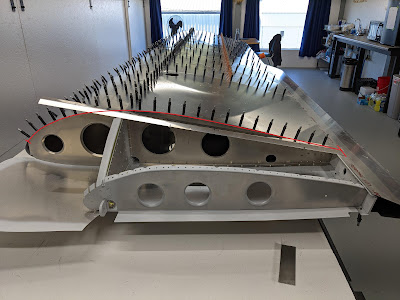

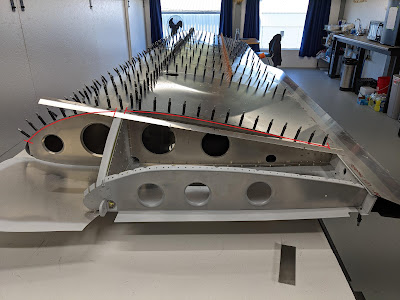

Then I moved on to drilling out the trailing edge. I still couldn't get the holes to quite line up just right, so I just went for it. The trailing edge on wing tip side is higher than the inboard side. Since the holes were already pre-drilled, I couldn't really make any adjustments.

I was going to then try to work on the wing root angle. The drawing looked like the angle was one piece and ran from the rear channel to the nose tip. I apparently just wasn't thinking clearly today, but thankfully the FB builders helped me out. I believe this angle gets cut in two pieces and actually goes in front of the rear channel and not on top of it. I decided to just stop here for today, since I seemed to be having an off weekend, lol.

This is where I thought the wing root angle was supposed to go.

I thought it went from the rear channel all the way up to the

nose as one piece, and it's definitely not long enough for that.

This is where I believe it goes now.

Back piece, starts before the rear channel and stops at the spar.

Front piece goes from spar to nose tip.

Build Time: 4 hours 15 minutes